You get tons of energy savings from recycling scrap metal. Here’s how.

We’ve all heard the old line: if you love trees, there’s an easy way to help protect them. You can recycle paper. That reduces the need to cut down more trees.

Less well known is that the same line could be used when it comes to the recycling of scrap metal. That includes everything from used parts in your car to old appliances.

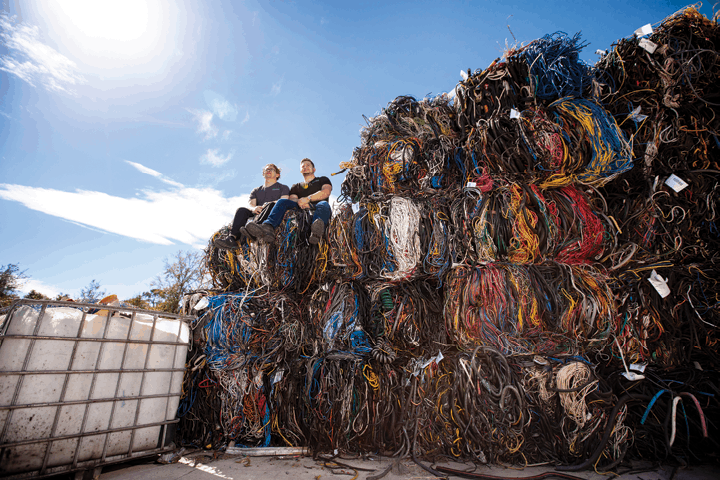

With scrap metal, though, the recycling process is about boosting something just as important: energy. If your scrap metal goes to a recycling company like GLE Scrap Metal rather than to a landfill, that helps provide another big boost to the environment.

Quite simply, recycling scrap metal is a very eco-friendly move. The production of iron, steel and aluminum is an energy-intensive process.

It’s been estimated that this process represents 10 percent of the total amount of manufacturing energy use.

Recycling enables us to cut down on metals production. That saves energy and helps make this a more energy efficient industry.

What does Secondary production refer to?

Steel is made from iron ore, while aluminum is made from bauxite ore. This process is called primary production, and it’s energy-intensive.

On the other hand, Secondary Production – the use of recycling scrap to make steel and aluminum – is much more energy efficient.

The U.S. Department of Energy notes that secondary aluminum production requires 90 percent less energy than primary production.

Energy conservation is one of the biggest benefits of recycling metals.

So what’s the importance of using less energy? Estimates are that energy savings from recycling metals could power American homes for one year – and up to 20 million homes at that.

How do we boost the environment through recycling?

Think of it this way: if we’re not recycling metal, it would be necessary to drill the earth for ores, so we could procure metals from them.

It’s a lengthy process, quite expensive, and requires huge amounts of water and petroleum. Recycling not only saves space in our landfills, but plenty of kilowatts of energy.

The environmental benefits extend beyond energy savings. Ores found deep in the earth are a finite resource, with a limited supply.

Recycling metals means we’re less likely to eventually exhaust that supply.

Remember the old line about how recycling paper saves our trees? Turn out, so does recycling metal.

Drilling and manufacturing new metals requires a lot of deforestation — cutting down acre after acre of trees to clear the land for mining and drilling.

What are the additional advantages of metal recycling?

The biggest disadvantage of drilling for ore is the harm that poses to the environment. It causes soil, air, water, and noise pollution. It depletes the natural resources of the planet.

That’s where you come in.

If you have metal products you no longer need, recycle them. Virtually every metal can be recycled.

Fewer resources are used to create products from scrap metal, since they have already been refined and processed. It takes waste out of our landfills.

We also significantly reduce our risk of polluting the soil and water.

Best of all, recycling metal or salvaging scrap metal and selling to recyclers is a great source of additional income. Some metals, like copper wire and gold plating, are particularly valuable.

Energy Savings from Recycling

Finally, recycling metals remains one of the most earth-friendly activities possible. It’s imperative that we keep promoting it vigorously. If we keep drilling the earth for new ores, it’s likely that future generations will eventually run out of these precious resources.

Instead, contact GLE Scrap Metal today to continue the practice of recycling every piece of metal that you have. Selling us your scrap metal is a way to put money in your wallet.

Because this is also a great way to help save energy, to make our environment cleaner, and to protect our natural resources. It even helps save our trees.

To learn more, call GLE Scrap Metal today at 855-SCRAP-88.