A strong economy is helping particular sectors grow at an accelerated rate, and a great example is the construction industry. A low unemployment rate has produced significant public and private sector investments in major construction and infrastructure projects.

And as more commercial and residential properties get built, more road expansion projects get launched, and new industrial plants are constructed, that work is boosting other industries.

A clear winner has been the scrap metal industry, and business analysts predict this field will experience significant growth through 2021.

It isn’t just because the U.S. economy is strong. The metal recycling industry is expected to grow in importance worldwide as more and more developing countries move toward industrialization.

That growth puts pressure on these nations to take on the challenge of disposing of scrap waste and minimizing the economic problems it creates. More and more nations are investing in recycling as they grow and become more urban in nature.

Because in the U.S. right now, the scrap metal industry is riding the wave of economic development in North America and Europe and urban growth in developing countries. In fact, scrap metal accounts for up to $90 billion in economic activity in the U.S. alone.

Scrap metal recyclers have not only become the employer of thousands of workers, but their industry revenue has increased over the past few years.

The scrap recycling industry plays a key economic role in the U.S. economy today. By buying excess scrap from businesses and construction sites, scrap recyclers offer manufacturers and factories an income stream, while allowing both to keep their plants and work sites clear of piles of metal waste.

Scrap metal can also be reused over and over again, making it ideal for manufacturers that want to hold down production costs.

Those recyclables have additional value, contributing not only to the economy, but also our environment.

And a new report indicates that growth is here to stay.

Will the Scrap Recycling Industry Stay Healthy?

A new report, “Worldwide Scrap Metal Recycling Market 2021 Development and Growth Forecast,” indicates that metal recycling will continue to grow, thanks to increased recognition that scrap metals are not disposed of but reconfigured to help manufacture new products.

The report notes that scrap metal recycling has become more popular over the past few decades, since it offers both energy savings and cost benefits. Using recycled scrap allows companies to avoid the costlier need to mine for virgin ore, which puts considerably more pressure on our natural resources.

Recycling scrap is also less costly for businesses using recycled metals, which are used as raw metals in the manufacturing processes.

Right now, 40 percent of worldwide steel production is made using recycled steel as a raw material.

As a result, the Global Recycled Metal Market is expected to experience an annual growth rate of 3.8 percent between 2018 and 2025, the report noted.

The primary drivers for recycled scrap metal remain the financial incentives for manufacturers, along with the environmental benefits from recycling.

North America remains the largest consumer market for recycled goods, with up to 42 percent of crude steel in the U.S. being made using recycled materials.

In fact, there’s been an increased demand for recycled metals due to an increase in productivity in the automotive and construction sectors, thanks to the healthy state of the economy.

But the important role that scrap metal plays in the economy and in promoting a healthier environment is increasingly recognized worldwide. In recent years, the Asia Pacific region has also seen steady growth in the recycled metal markets.

Countries with developing economies, including China, India, Japan and Australia, are driving the demand for recycled metals.

In addition, scrap metal recycling in the U.S. remains an important source of supply for developing countries that need metals to supplement their growth.

Another key factor: increased urbanization in heavily populated nations like China and India, and the increasing awareness in both countries of waste management and resource efficiency. Those are two of the factors boosting the Asia-Pacific metal recycling market.

Recycled raw materials have helped to lower production costs for the automotive and shipbuilding industries in Asia, and to lower energy usage and reduce the emission of greenhouse gases.

Another reason for the anticipated future growth in the metal recycling market is an increasing number of government regulations on waste recycling and management. Those regulations have been designed to help protect natural resources and the environment.

Rapid industrialization and imposition of strict laws pertaining to waste management and recycling are also major factors contributing to the growth of the metal recycling market.

There is also rapid growth occurring in the Middle East construction sector, mainly due to an increased investment in infrastructure projects by both the private and public sector.

The robust growth in transportation and automotive sector is also expected to trigger demand for recycled metals.

How Important are Environmental Issues to the Industry?

Global concerns about the environment remain one of the major contributors to the growth of the scrap metal recycling industry globally.

There’s a lot of scrap metal produced in the United States today – up to 150 million metric tons every year. Of that amount, 85 million tons is iron and steel, although other metals that produce large amounts of scrap include aluminum, copper, stainless steel, lead, and zinc.

Treating those metals as scrap can amount to both lost product and profits. We also know that if that scrap is treated as regular trash to be hauled away, it will end up in community landfills, which is an environmental disaster waiting to happen.

Scrap metals contain toxins like mercury and lead that can pollute the nearby soil and water, endangering both people and wildlife. That’s why there has been such a strong push to recycle scrap metal instead.

Fortunately, as the report noted, the scrap metal recycling industry has gotten stronger as the environmental risks of putting scrap in landfills have become better known.

This trend also works to the advantage of the business community, allowing companies to profit from something they used to consider trash to be disposed of. Companies paid for the metal they needed, but if they only used a portion of it, traditionally they simply throw the rest out.

Instead, they can sell their scrap metal to recycling firms that will then make it available to manufacturers for new uses.

The companies purchasing scrap metal from recycling firms can take advantage of less expensive metals for their productions, which also helps reduce their overall costs, while bringing them larger profits since they can offer their goods at a lower cost to consumers.

And, as part of the overall economic cycle, those lower costs put more money in the pockets of consumers, boosting the economy at large.

That’s a key reason why scrap metal recycling has become a big business today, creating more than 450,000 jobs, with those numbers expected to rise in the coming years.

The industry has also helped put $90 billion into the economy each year and scrap metal and items made from recycled scrap metal are a major export for the U.S. This nation exports about $14.5 billion worth of scrap metals and products made from them.

As the report recognized, each year the U.S. recycles more than 120 million metric tons of scrap metal – which represents the majority of the 150 million tons it produces. Doing that takes a considerable burden off our environment.

And during this boom economy, which is encouraging more construction across the U.S. and the industrialization of emerging nations, the scrap metal recycling industry appears to be on the verge of more growth in the years ahead.

Conclusion

Scrap metal recycling is set for solid growth in the next few years as the global economy gets stronger. It also helps that consumer demand for cars and other products is ramping up the manufacturing process.

Many of those manufacturers are recognizing the economic and environmental benefits of using recycled scrap in the production process.

And we can all play a part by recycling the scrap that we have and no longer need, and constantly contributing to the scrap recycling process.

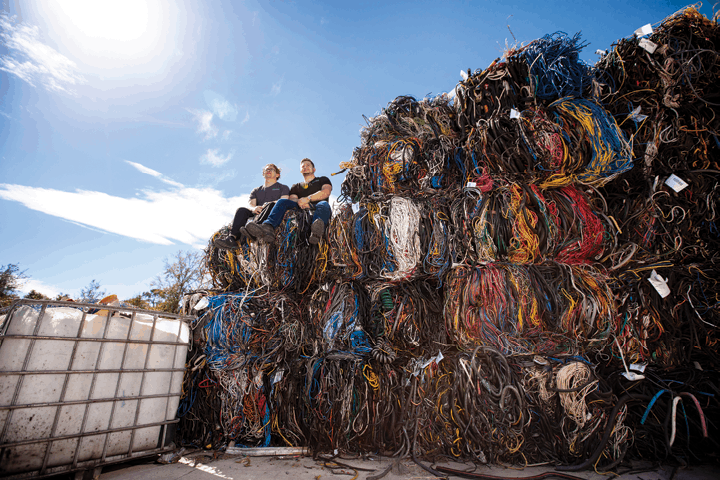

Individuals and businesses can bring their scrap to GLE Scrap Metal, a premier scrap metal and electronic recycler that performs environmentally-friendly processing and recycling of all base and precious metals.

This family-owned and operated business works hard to preserve our natural resources and to help all of us conserve energy. And GLE supplies domestic mills and global end-users with wide ranges of raw commodities that can be transformed into new products. That’s a great way of ensuring that excess materials don’t go to waste.

To learn more, call GLE Scrap Metal today at 855-SCRAP-88 to request a quote.