Unfortunately, modern factory pollution hasn’t gone away since the introduction of the industrial revolution, and it probably won’t anytime soon. While we struggle to become more carbon-neutral, working against industrial emissions is something design engineers are trying to tackle today.

In order to find the right solution, engineers need a financially viable option that doesn’t introduce new problems. The good news is that there are three relatively simple solutions that manufacturers can use to do just that.

Those three methods involve changing the method of construction, the way businesses source their metals, and the efficiency of their metals recycling. Why is that so important? Well, manufacturing makes up an increasingly larger portion of our carbon footprint.

Factory Pollution Is A Well Known Problem

The reality of industrial emissions’ role in pollution and our collective carbon footprint are relatively well known. Most people understand that manufacturing pollution makes a large piece of the puzzle, but how big the piece is up for debate.

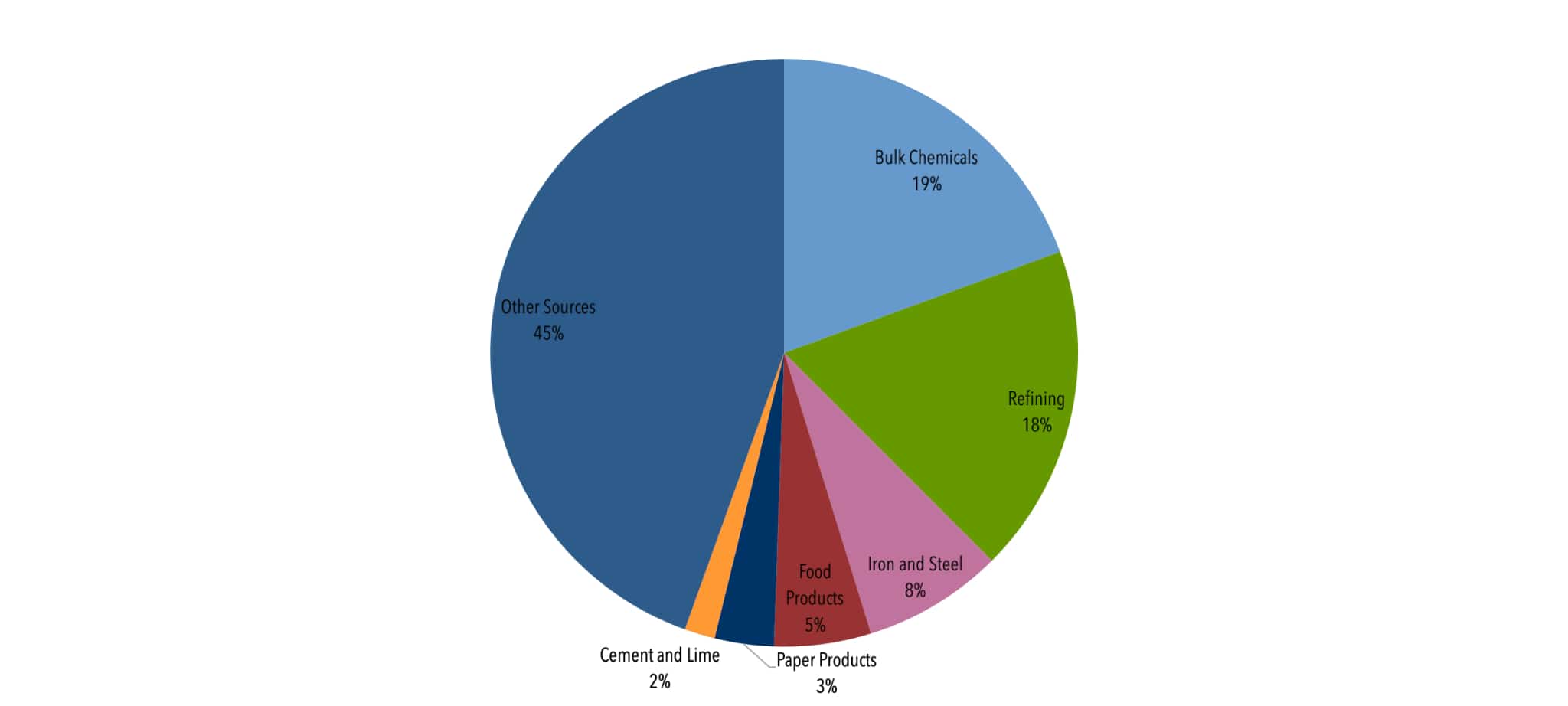

In 2020, the US Energy Information Administration produced a report detailing what industrial processes made up industrial emissions. This report detailed that factory pollution was found to make up 29.3% of total emissions in the United States, including direct and indirect emissions.

Between refining and virgin ore production, 26% of that factory pollution can be reduced with better recycling, construction, and sourcing methods.

Method 1: Construction

Two new formats of construction have started to emerge that show promising results for both carbon emissions and cost of construction: additive manufacturing and tessellation structures.

Is Additive Manufacturing Really A Solution?

If you don’t already know, additive manufacturing is another name for 3D printing. It’s a way to ‘print’ designs through a modular particle method. Metal additive manufacturing has the ability to create less material, heat, and water waste, while using cheaper source materials made out of nodules and grains of metal.

The problem lies in the weaknesses the process involves. Mainly, slow production speeds and inconsistencies in material properties.

Production Speed

Currently, 3D printing is more manageable in small and custom shops due to the incredibly slow speed of the manufacturing process. Fabrication labs and plants simply couldn’t keep up with the current demand using this method.

Due to time constraints, additive manufacturing isn’t quite at the level to compete with current fabrication levels. Once a handful of definitive case studies are revealed around the new method, it may be more possible to use in large-scale manufacturing.

Structural Integrity

The next problem facing 3D printing today is inconsistent material properties and structural integrity. Currently, the slower you operate the equipment, the more consistent the finished product.

The drop in precision makes this option completely unviable for electronics manufacturers, aerospace, and to some extent, food packaging. A lack of precision can interfere with modern chips due to their complexity and potential interruptions of connectivity. Not to mention potential lawsuits due to cuts or food or drink pollutants.

Aerospace also brings up the issue of the tensile strength of 3D printing and the ability to hold together in extreme changes in G-forces. Just as with production speed, this structural integrity problem will need more robust testing before it’s ready to be rolled out to a primary fabrication method.

What About Tessellation Structures?

Honeycomb and triangular mini, micro, and nano-structures is another potential answer to the problem. Lightweight structures often struggle with integrity much in the same way as additive manufacturing. By creating a low-density strong structural mesh in lightweight materials, you solve a number of issues.

For one, far less material is required, saving sourcing costs and producing a low-carbon product. In certain situations, these structures can actually end up with a higher tensile strength than solidly manufactured parts.

Creating New Problems

One of the potential problems honeycomb structures can introduce is a massively increased surface area. That may not seem like a problem, but after a certain threshold, physics starts to get weird. Take another recent invention as an example: aerogels.

Aerogels are a form of modern engineering purpose built with surface area in mind, but this effect could cause an issue when it’s not wanted. For example, most aerogels are highly electrically conductive while also having low thermal conductivity.

While this can seem like a bonus, this can quickly create a knock-on effect that makes the new structure incompatible for their purpose. Often, design engineers can’t simply choose a new material without knowing all of their properties and potential problems they can produce.

Sealed Products

It can seem rather obvious, but a material filled with holes that can’t have holes by design can make it a terrible solution. Of course, this is dependent on the size of the structures; a nano-structure won’t leak water or necessarily let air pass through a container.

But that change in size of the tessellation can turn into the same problem as additive manufacturing; the more complex it is, the longer it takes to manufacture.

These structure changes are far more viable than additive manufacturing at the moment, but for many manufacturers, it simply isn’t financially feasible to take on.

Method 2: Choosing Better Source Materials

If you can’t afford experimental methods of construction to reduce your industrial emissions, what can you do? The refining process of new materials makes the bulk of easily changeable solutions for all manufacturers at a whopping 18%. Choosing more eco-friendly materials make for an easy win.

Metal Grading

Steel, aluminum, alloys, and few other metals have different properties, separated by grades. Each of these grades have different applications, of which design engineers are well aware.

Certain metal grades are extremely hard to produce from recycled materials. Luckily, recycled metal is often cheaper both economically as they are ecologically.

Source Availability and Demand

Of course, the largest issue comes from a lack of supply, not demand. Most manufacturing managers make an effort to introduce recycled materials as part of their sourcing process. It seems logically, with so much metal having been produced in the past, the availability of those metals should be abundant, right?

Not so much. As it turns out, the problem comes from a lack of our third method being used.

Method 3: Improved Recycling

A fair number of fabricators and product manufacturers do recycle their metals. The problem lies in the number of them recycling and how efficiently they do so. While Coronavirus has forced some incredible shifts in diversifying sources and transportation, it’s had a more dramatic effect on the principles of lean manufacturing.

While remanufacturing is starting to slowly rise, improving your factory’s metal recycling is another way to save costs. Not only is it one of the easiest to achieve between the methods shown above, but recycling businesses like GLE help you create logistical plans and procedures to make it even easier.

In the end, lowering your carbon footprint not only helps drive innovation and future technologies, but it’s almost always the best financial choice. It’s possible to help the planet and create a quality product.

GLE Scrap Metal

GLE Scrap Metal is a National Scrap Recycler with locations in Michigan and Florida. We can help your business with industrial, municipal, and commercial scrap. If you need help arranging a commercial pick up, or just looking to create a recycling plan to save your business money and fight pollution, give GLE a call.

We’ll help you create a comprehensive scrap recycling plan for your business. If you’re looking to help but don’t own a business, see our locations for residential recycling and help provide relief to local pollution.