In today’s resource-conscious economy, more industries than ever are turning to scrap metal as a primary source for manufacturing materials.

Using recycled metal not only reduces waste and energy consumption but also supports a more sustainable, circular economy, where materials are reused instead of discarded.

Let’s take a closer look at the top five industries that rely on scrap metal for production and why it matters.

Industries That Rely On Metal For Production

While every business may interact with metal, here are some industries where metal is vital in their day-to-day production.

1. Construction & Demolition (C&D)

The construction industry is one of the largest consumers of metal, including:

- Steel beams

- Rebar

- Wiring

- Piping

- Fixtures

- Heaters

- Gutters

- Hinges

- Appliances

Additionally, demolition projects also generate massive amounts of scrap metal, much of which is recycled and reused in new construction. By using scrap metal instead of virgin materials, construction companies can significantly reduce their carbon footprint of a project.

Many modern developers prefer companies that adhere to green building standards. This makes recycled metal a win-win for both sustainability and cost-efficiency.

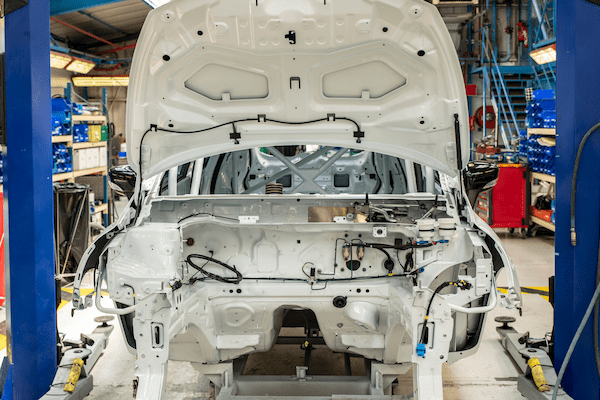

2. Automotive

From car frames to engine components, vehicles require large amounts of metal. Fortunately, the automotive industry has long been a leader in scrap metal usage.

In fact, the average vehicle today contains about seventy-five percent recycled steel and aluminum.

- Car frames and chassis

- Body panels

- Engines and transmissions

- Brake rotors and calipers

- Exhaust systems

- Copper wiring

- Wheels and suspension parts

- Interior reinforcements

- Safety cages

Using recycled materials helps car manufacturers save on production costs and meet environmental regulations, all while delivering high-performance products.

3. Aerospace & Aviation

Precision, safety, and strength are crucial in the aerospace industry, and metals like titanium, aluminum, and nickel alloys are used extensively.

- Aircraft fuselage and wings

- Jet engines and turbine blades

- Landing gear

- Fuel and hydraulic systems

- Fasteners, bolts, and structural connectors

- Interior components

- Avionics enclosures

As aerospace companies look to reduce their environmental impact, scrap metal recycling is playing a bigger role.

While aviation-grade metals must meet stringent quality standards, advancements in recycling technology have made it possible to reclaim and reprocess high-grade alloys without sacrificing integrity or performance.

4. Electronics

Electronics may seem small in size, but they rely on a wide array of metals:

- Copper wiring

- Casing

- Data centers

- Storage components

- Cooling systems

- Circuit boards

As demand for devices like smartphones, tablets, and laptops grows, so does the need for responsible sourcing of materials.

Using recycled metals to manufacture electronics not only lowers production costs but also helps mitigate the environmental damage associated with mining rare minerals.

One significant source for electronics manufacturers to recover valuable metals is discarded devices, known as e-waste.

5. Machine Manufacturing

Equipment and industrial machinery use large volumes of metal parts, making machine manufacturing a key player in the scrap metal ecosystem. Whether it’s for agricultural machinery, factory equipment, or tools, manufacturers often rely on recycled steel and aluminum to build durable, high-performance machines.

- Machinery frames and housings

- Gears, bearings, and shafts

- Cutting tools and dies

- Hydraulic and pneumatic components

- Conveyor systems and rollers

- Fasteners, brackets, and support components

Utilizing scrap metal also helps manufacturers keep prices competitive while supporting global sustainability goals. Additionally, machine production generates substantial scrap metal suitable for collection and recycling.

Why Production Scrap Metal Matters

Scrap metal is a powerful engine for long-term environmental sustainability, operational efficiency, and economic resilience.

In an era where businesses face growing pressure to reduce waste and operate more responsibly, incorporating scrap metal into your production cycle offers a strategic advantage on multiple fronts.

Cuts Down on Mining & Emissions

Mining raw materials like iron, bauxite, or copper takes a heavy toll on the environment, leading to:

- Habitat destruction

- Water pollution

- Increased greenhouse gas emissions

Using scrap metal, manufacturers can significantly reduce their dependence on mining operations. Instead of extracting and transporting raw materials from the earth, they can tap into a readily available supply of metals that have already been processed once.

Supports a Circular Economy

In a circular economy, resources are reused rather than discarded. Recycling scrap metal helps close the loop by turning waste from one product into the raw material for another, reducing landfill buildup and promoting sustainability.

It’s quite possible that scraps from your manufacturing may one day end up back in your plant in a new form.

Saves Energy & Natural Resources

Producing new metal from raw ore consumes much more energy than melting and reforming scrap metal.

- Recycling aluminum saves up to 95% of the energy needed to produce it from bauxite.

- Recycled steel uses about 74% less energy compared to steel made from iron ore.

- Recycling copper cuts energy use by up to 85% compared to mining

This also conserves valuable natural resources for future generations.

Reduces Material Costs and Improves Profit Margins

For industries that rely heavily on metal, raw material costs can represent a significant portion of production expenses. Using recycled metal helps stabilize and often lower these costs, offering a more predictable and affordable supply chain compared to volatile global metal markets.

Scrap metal is typically less expensive than virgin ore but offers the same strength and performance characteristics required for high-quality products. This allows companies like yours to maintain product standards while increasing their profit margins.

Recycle Your Production Scrap Metal

Scrap metal isn’t just trash; it’s a vital resource powering the construction of our buildings, vehicles, planes, electronics, and machines.

As recycling technology improves and industries continue to shift toward greener practices, scrap metal will play an even greater role in shaping the future of manufacturing.

Looking for the right home for your recycled metals? We have brokerage and trading services where we get our customers the best deal.

Have scraps from your production? Recycle your production scrap metal with our environmentally friendly facilities.

If your business is in one of these sectors, now is the perfect time to evaluate how scrap metal can improve your bottom line while benefiting the planet. Request a quote today!